FAQ: Discs & Rotor Kits

One of the other prime sources of brakes squealing is a rough edge or “lip” that forms along the outer edges of the rotor surfaces, because brake pads do not make contact with that area. The “lip” becomes more visual as rotors wear out and become thinner. Sometimes, the lip becomes high enough compared to the surface areas of the rotor, causing it to come in contact with brake pads that aren't designed with rounded corners, resulting in a squealing sound. Very cold winter temperatures cause the rotors to contract slightly which can also aggravate this effect, the same goes for getting the brakes extremely hot under repeated heavy use that can lead to metal expansion which also causes more contact on places where it shouldn't be.

If you notice a vibration that occurs only upon slowing down, your brake rotors need attention. In most cases, the vibration is a result of rotors that have an uneven surface for the brake pads to clamp onto. Often this vibration is incorrectly described as a “warped” rotor.

The term "warped brake disc" has been in common use in motor racing for decades. When a driver reports a vibration under hard braking, inexperienced crews, after checking for (and not finding) cracks often attribute the vibration to "warped discs". They then measure the disc thickness in various places, find significant variation and the diagnosis is cast in stone. In fact every case of "warped brake disc", whether on a racing car or a street car, has turned out to be friction pad material transferred unevenly to the surface of the disc. This uneven deposition results in thickness variation or run-out due to hot spotting that occurred at elevated temperatures.

To get rid of warping, an edge lip, or hot spots, it is best to replace the rotors entirelyto ensure optimal performance and longevity. Alternatively rotors can be taken off the vehicle and ground flat on both sides by a special lathe. Because this resurfacing process involves removing a good deal of thickness across the entire rotor surface, it's important to be aware of what your vehicle manufacturer's minimum rotor thickness specification is. This is the point where the rotor still contains enough metal to absorb and diffuse heat build-up without becoming warped, glazed, or fractured. If rotors will be below minimum thickness after re-surfacing, they need to be replaced instead.

|

|

| Brake disc showing unevenly transferred friction pad material | Brake disc showing uneven rotor wear |

The system is a direct replacement for the OE disc. No modifications are necessary.

The disc will bolt directly to the car and work with OE calipers and pads perfectly. Once the 2-piece rotor system is in place, simply replace the cast iron rotor when needed. Some discs are larger in diameter and come with caliper spacers. If longer bolts are required, they are also supplied.

A 2-piece disc will generally weigh between 4 – 8 lbs less than the OE 1-piece disc it will replace. This is due to the heavy cast iron hat section being replaced with lightweight, high strength aluminum. The mass of any vehicle requires energy to accelerate or decelerate. Reducing the vehicle mass improves acceleration, and requires less energy to be dissipated during deceleration. Rotating mass requires additional energy in order to increase or decrease its speed of rotation. Decreasing the mass of the disc has a great benefit due to reduction in rotational inertia. This will allow more of the braking force to be available to decelerate the vehicle, not the disc.

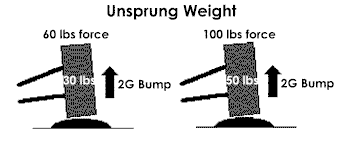

Additionally, the mass of the brake system is also unsprung mass. Reducing the unsprung mass has the additional benefit of improved suspension performance, resulting in enhanced ride and handling. Rotating masses require additional energy to vary the plane on which they turn. The lighter the disc, the quicker the response of the vehicle steering due to the reduction in gyroscopic effect/rotational inertia of the disc. The lower the unsprung weight, the less work the shocks and springs have to do to keep the tires in contact with the road over bumpy surfaces. Lot of problems, if not all of them is caused by inertia. Bigger weight means higher inertia. Higher inertia means more workload for shocks and springs to keep tiers on the ground. If unsprung components have a high mass they are harder to accelerate/decelerate and thus it is more difficult for the suspension to maintain a consistent tire load. As an example, compare the weight of the Ferrari 360 OE disc at 18.2 lbs, and the GiroDisc at 14 lbs. The GiroDisc is 4.2 lbs lighter per disc. Replacing all four discs will save 16.8 lbs of rotating, unsprung mass.

The edges of the slots on slotted discs continuously clean and refresh the pad surface. This will allow the pads to have a maximized friction surface always available. Additionally, they prevent containments from collecting between the pad and disc interface.

The disc is lightened, decreasing its rotational inertia.

Slots prevent the formation of a water film on the disc in wet weather, maintaining the best brake response.

A note on drilled discs:

We don't recommend drilled discs for high performance applications. The rapid heating and cooling cycles will cause cracking on the friction surface of a drilled disc. The use of high friction or racing pads will exaggerate this condition. Most pad manufacturers specifically recommend that their race pads not be used on a drilled disc for this reason.

Note as example the cracking in this OE Ferrari 550 drilled disc after one track day. Also note this custom front disc of a Porsche 993 Turbo after hard use.

|

|

| OE Ferrari 550 drilled disc showing cracks after one track event | Drilled disc showing cracks after one weekend of hard track use |

The answer is yes, for optimum performance, any time different friction materials or discs are introduced, a bedding procedure should be carried out.

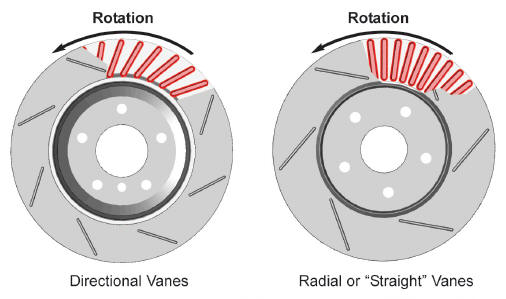

For maximum airflow and superior cooling, some performance rotors uses directional vanes. For a directional vane internally vented disc, the geometry of the vanes dictates the direction of rotation. A directional vane disc must be installed with the vanes running back from the inside to outside diameters in the direction of rotation. Your discs will come with labels indicating their correct placement on the vehicle. Orienting the disc in this manner creates a centrifugal pump. The rotation of the disc causes air to be pumped from the center of the disc, through the vanes, and out through the outside diameter of the disc. This greatly enhances the disc’s ability to dissipate heat. Discs installed backwards have limited cooling.

Login and Registration Form