Addressing Brake Squeal: Causes and Solutions

Let's delve into the intricacies of brake squeal and how to tackle it. Firstly, it's crucial to note that brake squeal can manifest with any brake system, regardless of type or brand, and on virtually any vehicle.

Key Facts:

- It's crucial to mention that a squeaking sound can occur if the brake lining wears down to the backing plate or if the mechanical wear indicator is triggered.

- The condition of the brake disc/rotor significantly influences squeal. A worn rotor with a lip or uneven surface can extend the duration of noise.

- Various types of squeal exist, ranging from the subtle "Creep Graunch" upon releasing the brake from a standstill to the more pronounced brake squeal mentioned in point 1.

- Brake squeaks also commonly stem from road and brake debris contamination of the linear sliding components within the caliper. This contamination affects the guidance of the caliper guiding pins that facilitate a caliper's movement over the saddle. Additionally, squeaking noises may be attributed to contaminated caliper pistons.

- Motorsport brake pads often generate more noise compared to those used in factory or street cars due to several factors, which you can read more about here.

Effective Remedies:

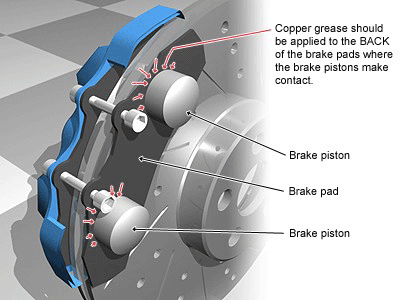

- Firstly, check the thickness and condition of all brake pads. Clean all linear guides, ensuring they are free of rust, and ensure that the brake pads can move freely at all times over the caliper or between the stainless steel guides and grease them lightly with ceramic paste.

- For cast iron rotors exhibiting uneven surface, the optimal remedy involves machining them on a brake lathe, provided thickness minimums are respected, as the cast rotor matrix settles over time.

- Make sure your brake pads are properly bedded in and have a clear pad layer transfer. If noise persists beyond 800 kilometers, subject the brake system to rigorous use with a few heavier brake applications on a safe road.

- Regularly inspect caliper condition. Calipers should be regularly cleaned, serviced and/or exchanged in accordance to the vehicles service manual and/or type of use. Corrosion in sliders and pins can cause pad drag, leading to brake overheat and squeal. When using performance-enhancing brake pads, we recommend checking them more frequently than prescribed due to a higher release of brake dust compared to OE or street brake pads.

- If noise persists despite the above measures, communicate with your brake supplier to explore a different pad option. At brakes-shop.com, we have an experienced sales team which is supported by a team of engineers to assist you in identifying issues, discovering solutions and find products that suit your use and budget. However, it's noteworthy that the incidence of noise on most street pads post-bedding in is nearly negligible.

Finally, Similar sounds that you may recognize from experience or the past do not necessarily indicate the same problem. Therefore, systematically check and maintain the entire braking system step by step, ensuring you take every measure to prevent further issues rather than repeatedly addressing individual problems.

|

|

| Example of copper grease application | Example of proper brake parts lubricant |

Exploring the Correlation Between Motorsport Brake Pads and Brake Noise

Motorsport or race brake pads are designed to perform on the racetrack and known for producing more noise than street-oriented brake pads, even during normal street driving.

Here's a Breakdown of the Reasons Why:

- High Friction Formulation: Motorsport or race brake pads are designed for high-performance and aggressive braking. They typically have a higher coefficient of friction to provide better stopping power. However, this high friction can lead to increased noise, especially under heavy braking.

- Temperature Range: Motorsport brake pads are engineered to operate at much higher temperatures than typical street pads. The extreme heat generated during intense braking can result in the pads vibrating and producing noise.

- Material Composition: The composition of motorsport brake pad materials is optimized for performance rather than comfort. While this enhances braking capabilities, it can also contribute to increased noise levels.

- Lack of Noise Reduction Features: Motorsport brake pads often prioritize performance over noise reduction features found in street pads. In the pursuit of superior braking capabilities, measures like noise shims or insulating materials, may be sacrificed. Moreover, certain noise reduction solutions are impractical in motorsports, as they tend to melt under the high operating temperatures, posing a risk of damage to the brake system.

- Aggressive Pad Bite: Motorsport pads are designed for quick and aggressive pad bite, which is essential for racing situations. However, this aggressive bite can lead to noise, especially during initial engagement.

- Limited Street Use: Motorsport brake pads are not typically designed for daily street use. When used on the streets, the conditions may not be ideal for these high-performance pads, leading to increased noise, wear and reduced performance.

- Vibrations and Harmonics: The high speeds and forces involved in motorsport can generate additional vibrations and harmonics in the braking system, contributing to noise production.

It's important to note that while motorsport brake pads may be noisier, they excel in providing the necessary braking performance for racing conditions. For daily street use, manufacturers prioritize a balance between braking performance, noise reduction and comfort, resulting in quieter brake pads.

Login and Registration Form